Lead Smarter

Solve Faster

Boost Your Bottom Line

Stop firefighting and start finding what matters. Build unstoppable problem-solving cultures that drive performance, eliminate waste, and sustain long-term profits.

25+ Years Experience

$100M+ Problems Solved

Top 2% Viewed TEDx

Recurring Problems Are Silent Profit Killers

Recurring problems cost you customers. They drain profit, burn out your best people, and trap leaders in endless firefighting instead of moving the plant forward. If fixes don’t hold under production pressure, you don’t have a solution. You have a delay.

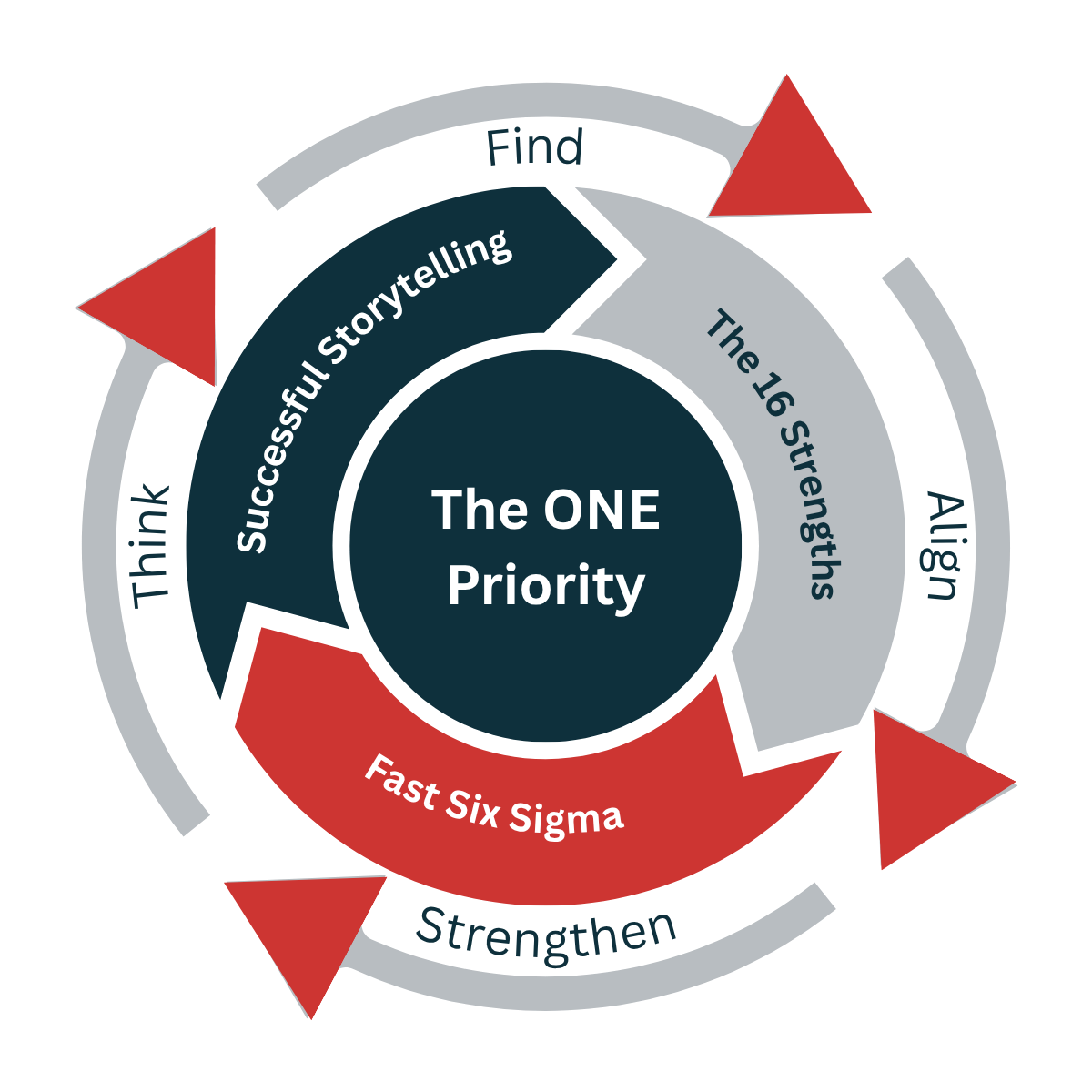

The ONE Priority

Your people aren’t asking for another list of “top 10 priorities.” They’re looking for The ONE Priority. The Only Necessary Effort that clearly tells them what winning looks like. It’s not always a problem; often it’s the primary goal and measure of the organization. The one outcome that, if achieved, makes a lot of other work easier or unnecessary. When leaders consistently direct time, resources, and attention toward that single, most important result, firefighting slows down, clarity shows up, and the work finally adds up to something that matters.

Ready to Build a Problem-Solving Team?Don't Do Band-Aids.

Build Bulletproof Solutions.

Michael built systems that turned repeat issues into permanent wins across automotive, medical, and consumer products.

- ▸ 25+ years in manufacturing quality management and operations at six of the Top Ten Automotive Companies in the world

- ▸

- ▸Developed multiple Advanced Problem Solving groups; solving over $100M in quality/production issues

- ▸Lean Six Sigma Master Black Belt; Shainin Red X Journeyman, Certified Member of the Maxwell Leadership Team, Distinguished Toastmaster

- ▸ Top 2% most-viewed TEDx talk on problem solving

Michael’s TEDxGreenville talk, “Teaching Kids Better Problem Solving,” challenges the way we prepare the next generation for an unpredictable future. Instead of memorizing answers, kids need to learn detective skills, teamwork, and leadership. The same strengths which drive success in the real world. His message clearly resonated: the talk has climbed into the top 2% percentage of most-viewed TEDx talks.

Coming soon:

Successful Storytelling™ for Leaders:

Turning complex ideas into “sticky” stories people remember and act on.

How We Help Manufacturers Win

From conference stages to plant floors, we equip leaders and teams to stop firefighting and start fixing what matters.

Speaking

Inspire & Spark Change

High-energy, story-driven keynotes that make problem solving stick. We turn abstract concepts into practical “aha” moments leaders remember and act on.

Outcomes:

- Align leaders and teams around the ONE Priority so recurring problems stop.

- Shift from firefighting to problem finding. Clarify the real problem fast and pick the right target.

- Turn data into decisions with a practical storytelling framework that earns buy‑in.

- Spark measurable momentum with simple tools people can use the next shift

Best for: Conferences, leadership summits, all-hands kickoffs

Training

Build Problem-Solving Teams

Hands-on workshops for leaders and teams who need to stop patching and start solving. People leave with simple tools, clear frameworks, and the confidence to deliver measurable results back at work.

Outcomes:

- Focus on the vital 20% of tools that solve 80% of problems, aligned to the ONE Priority: make recurring problems stop.

- Turn analysis into persuasive stories that earn buy‑in and speed decisions across functions.

- Unlock team potential by developing the 16 Strengths, leading to faster solutions and sustained improvements.

Best for: Plant teams, quality/ME/ops leaders, cross-functional squads

Coaching

Develop Leaders Who Deliver

One-on-one and small‑group coaching that aligns leaders to the One Priority: make recurring problems stop. We develop the 16 Strengths, sharpen decision quality with storytelling, and coach through your real situations with cadence and accountability.

Outcomes:

- Identifying and personalizing the ONE Priority for your role, team, and plant.

- Build the 16 Strengths at the leader level mindsets and habits that create self-sufficient, high‑trust teams.

- Craft and deliver clear, persuasive stories that earn buy‑in up, down, and across, so decisions move faster with less friction.

Best for: Executive teams, high‑potential managers, cross‑functional squads, and technical leaders

How We Solve Faster and Make It Stick

Simple enough to use tomorrow. Rigorous enough to hold under production pressure.

We use a simple, rigorous system built on the vital 20% of methods that solve 80% of problems—aligned to the ONE Priority: make recurring problems stop.

- Find: Cut through noise to identify the problem draining performance. We separate symptoms from the dominant cause and align everyone on one clear target.

- Align: Bring leaders and teams onto the same page by aligning to The ONE Priority, using data to make decisions around a single, clear story of the problem and what success looks like.

- Strengthen: Build the 16 Strengths of Successful Problem Solvers into daily behavior so teams collaborate better, challenge assumptions, and sustain improvements without heroics.

- Think: Stop firefighting and think decisively - using evidence, simple tools, and structured problem-solving to choose the smartest next move, not just the fastest reaction.

See How Manufacturing Professionals Are Applying What They Learned

“I now approach problems using statistical methods instead of gut feel.” S.P.

“I left with practical tools for problem solving and using tangible data to make decisions.” O.J.

“I’ll think through my stories differently and focus on becoming a better communicator.” E.V.

“I plan to use the information daily to maintain my skills and keep problem solving top of mind.” W.F.

“Knowing how to tell the difference between good and bad data will help us make better process decisions.” K.M

We won't send spam. Unsubscribe at any time.

© 2025 Protean Quality Systems, LLC

713 E. Greenville St. Suite D #242

Anderson, SC 29621

+1 (821) 777-2805

info@themichaelarnold.com

Privacy Policy | Terms of Service